Introduction

Glass, with its clear attraction and versatile applications, has actually ended up being an indispensable part of modern design and layout. Crafting elaborate shapes and sizes from this delicate material requires a skilled hand and the right tools. Among these tools, the glass cutter attracts attention as a necessary tool for artisans and specialists alike. In this post, we look into the art of precision reducing with a concentrate on the glass cutter– its kinds, use, and the skill required to master this delicate craft.

Kinds Of Glass Cutters

Standard Glass Cutter: The standard glass cutter includes a small, sharp reducing wheel placed on a steel handle. This kind is commonly made use of for straight cuts, creating precise lines on the glass surface area. The wheel ratings the glass, developing a weak point that promotes regulated splitting.

Oil-Fed Glass Cutter

This kind includes a tank for cutting oil, which oils the reducing wheel throughout procedure. The oil not only lowers friction but also assists keep the wheel cool, avoiding it from overheating. This is particularly helpful when servicing thicker glass or for extended reducing sessions.

Pistol-Grip Glass Cutter

Featuring a pistol-shaped take care of, this cutter uses a much more ergonomic style, giving a comfortable hold during extended use. The style boosts control and reduces hand fatigue, making it a preferred choice for specialist glass workers.

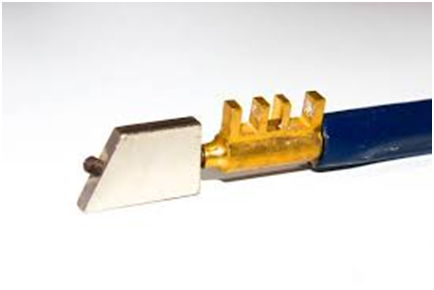

Carbide Wheel Glass Cutter

Unlike typical cutters with steel wheels, carbide wheel glass cutters have a wheel constructed from tungsten carbide. This product is harder and more resilient, enabling smoother and extra accurate cuts. Carbide wheel cutters are appropriate for cutting thicker glass and are favored for their longevity.

Diamond Glass Cutter

Employing a cutting wheel tipped with industrial-grade diamonds, this kind is specifically created for cutting complex patterns or curves. Diamond glass cutters excel in accuracy and are typically used in stained glass or creative glass work.

Usage and Methods

Rating: The key feature of a glass cutter is to score the glass surface. This includes running the reducing wheel along a fixed path, creating a visible line on the glass. The pressure used throughout racking up is important; it ought to be solid sufficient to develop a rating, but not so extreme that it brings about breakage.

Breaking: After scoring, the glass requires to be broken along the scored line. This is commonly done by using controlled pressure on either side of ball game, creating the glass to break easily along the damaged line. Techniques such as tapping, snapping, or utilizing pliers might be used, relying on the project requirements.

Personalized Cuts

Glass cutters are functional devices that allow for a range of cuts past straight lines. Skilled craftsmens can develop contours, circles, and detailed shapes by controling the cutter along particular courses. This requires a combination of experience, precision, and a keen eye for information.

Safety Considerations

Safety Equipment: Collaborating with glass demands the use of proper security gear, including safety glasses to protect the eyes from glass shards, and hand wear covers to shield hands from prospective cuts.

Work space Prep work: Clear and tidy your work space before reducing glass to reduce the risk of accidents. Remove any unneeded things, and make certain the glass is effectively supported on a level, stable surface area.

Final Thought

The glass cutter, an apparently straightforward device, is a portal to the globe of accuracy and creativity in glass work. From creating practical items in architecture to complex layouts in artistic endeavors, the glass cutter remains a vital instrument for those who seek to shape this delicate product with finesse and accuracy. As innovation advancements, brand-new innovations in glass cutting devices remain to arise, pushing the limits of what can be attained in the world of glass workmanship.